Turbocharger function in diesel engines – Speaking of turbochargers, four-wheeled vehicle lovers will know the name. Turbochargers are often found in four-wheeled vehicles with diesel engines, such as trucks and other four-wheeled vehicles that use diesel engines. Turbocharger is also a very important component in diesel cars, because it is capable of producing very high power.

Diesel cars usually have turbo engines. The goal is to increase engine power and the sound produced becomes smoother. Turbo itself is a forced intake system that can increase engine power by utilizing exhaust gas from the engine.

However, the turbo on a diesel engine can fail due to several factors. Some of them are due to damaged gaskets, too much engine oil burning and rarely paying attention to cleaning the air filter.

As proof of the existence of this one component, it is certain that the car’s diesel engine does not have any residual power or strong engine power. So, for the discussion this time, we will try to discuss what is a turbocharger? functions, benefits, and how it works on diesel engines.

For this reason, in this discussion, we have collected information about turbocharger sundries and their various functions that are interesting to discuss.

Further related information you can see below!

What is Turbocharger?

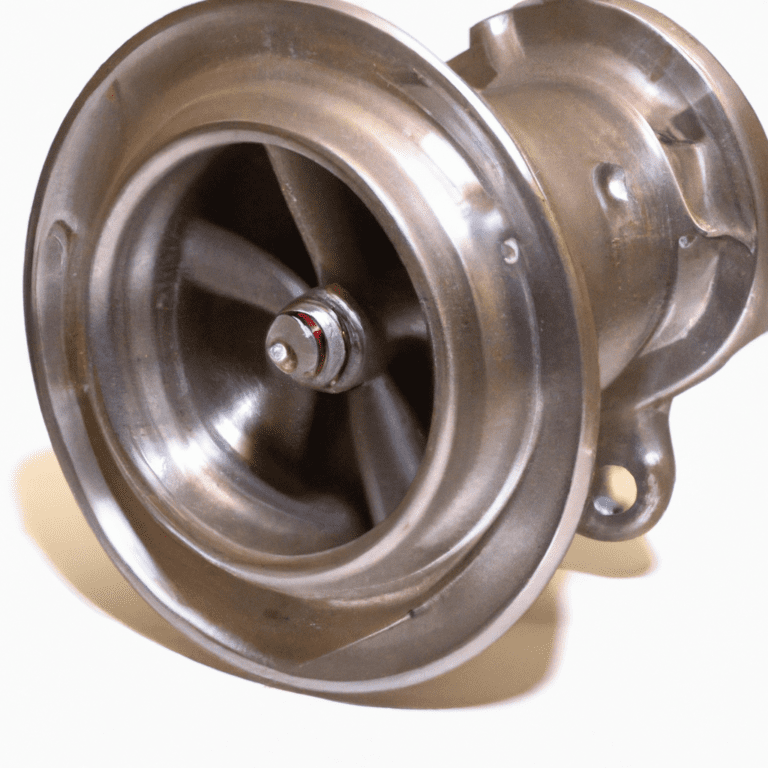

A turbocharger is a centrifugal compressor that gets its power from a turbine powered by vehicle exhaust. Often used in internal combustion engines to increase engine power and efficiency by increasing the air pressure entering the engine. The main advantage of turbochargers is that they significantly increase engine power for just a little extra weight.

The turbocharger was invented by Swiss engineer Alfred Büchi. His patent for a turbocharger was applied for in 1905. Locomotives and ships with diesel and turbocharged engines began to be seen in the 1920s.

The disadvantage of gasoline engines is that the compression ratio must be reduced (to avoid exceeding maximum compression and to avoid knocking), which reduces the efficiency of the engine at low power. Specially designed turbocharged diesel engines do not have this drawback. However, when operating at altitude, the increase in turbocharger power greatly affects the total output of the two types of engines. It’s the latter factor that makes turbocharged aircraft engines so profitable; and this is the first idea to develop this tool.

The engine component has three main parts: turbine wheel, compressor wheel and camshaft. The turbine wheel with the blades rotates with exhaust gas pressure, then through the rotating shaft of the turbine wheel, the compressor wheel also rotates with the blades in such a way as to pump air into a solid mass. Since these components frequently rotate in excess of 80,000 rpm, good lubrication is essential.

In 1970, Mercedes Benz launched a turbocharged car, namely the Mercedes Benz 300 SD, followed by the Chevrolet Corvair Monza and Oldsmobile Jetfire which pioneered the emergence of turbocharger technology in the automotive world.

It can be said that since the introduction of cars with the principle of operating a turbocharger, the social stigma towards turbocharged diesel engines has changed.

Turbocharger is a part of a diesel engine that is useful for increasing engine power due to the volumetric efficiency of air entering the combustion chamber.

The working principle of the turbocharger is forced induction with the main stock, using air from the exhaust of the vehicle, which is fed and directed to the combustion chamber.

Forced induction or forced induction itself is a process where compressed air is supplied and directed to the engine intake to burn fuel in the combustion chamber.

Puts extra pressure to produce power in the form of better engine efficiency. The turbocharger also has turbo pressure sensor technology which functions as a manifold pressure reading, which is then changed by the engine ECU to increase the amount of fuel injected by the injectors.

Turbocharger function?

One way to increase the power/efficiency of a diesel engine is to use a turbocharger. The working principle of the turbocharger is to use exhaust gas heat as energy to compress the combustion air so that high power is achieved. The exhaust gas from the combustion of each cylinder is then directed through the exhaust manifold, which then expands to the turbine-side turbocharger, creating mechanical energy which is then used as power to rotate the fan-side turbocharger.

Now that the fan is on the intake side, the combustion air increases on the intake manifold side of the diesel engine. A powerful car engine requires a larger number of cylinders than usual. Therefore, it is natural for sports or racing cars to have more cylinders than cars of other classes.

Cars with 6 cylinders, 8 cylinders, even 12 cylinders are suitable for sports or racing cars. The role of the cylinder in a car is to store fuel and oxygen, which are then burned to produce better and bigger engine power.

No wonder if you want to get maximum performance from a car engine, you need a large number of cylinders. What about cars with less than 6 cylinders? Can’t get more car performance? Of course it can be equipped with a turbocharger that uses the principle of forced induction or forced induction.

By forcing a certain amount of air into the cylinder chamber through the compression process, the air in the cylinder chamber which is then burned becomes denser and contains more oxygen, resulting in much greater power after combustion.

It is not surprising that the turbocharger increases engine torque and power, improves fuel economy, improves engine power characteristics that are initially small or large, but can still reduce engine emissions.

Turbocharger Benefits

1. Fuel efficient, because the rest of the combustion is compressed and returned to the combustion chamber

Installing a turbocharger on a diesel car that has been required and proven by several test results shows that a machine with perfect technology can reduce fuel consumption.

2. More environmentally friendly, because there is a lot of air in the engine, so the combustion process is more optimal

The presence of this technology is not only economical, but can reduce most of the emissions, making diesel cars more environmentally friendly, even the emissions that are visible when the engine is running. active, not as dense as a car without a turbocharger.

3. Increasing diesel engine power

The third advantage is that the car’s performance has obviously improved because the exhaust heat can be reused to make the engine more efficient, making the car more powerful and have a stronger performance.

4. Engine noise is reduced because the exhaust duct is used to turn the turbine

The sound of a real diesel engine is loud because of the large movement, with the turbo the sound is still smooth, but still has a manly aura because of the distinctive sound of the turbocharger.

5. Not Wasteful of Fuel

More economical in terms of fuel consumption, so you can travel freely without having to go back and forth to gas stations.

6. Reducing power loss at altitude because the air at altitude is very thin, so the amount of air entering the turbocharged engine is stable

Getting a turbocharger for a diesel engine has a huge advantage, especially for those of you who live in the mountains, because the way this technology works can increase the amount of air that enters the engine, even though the air is very thin. outside the car.

7. Optimum combustion process engine structure. small and light turbocharger, but always very high power 30-60 %

The light and small size of the turbocharger certainly makes the car cleaner under the hood, but on the other hand, such a large output power can also be increased.

The use of turbochargers in diesel engines has many advantages, so it is not surprising that currently there are many cars on the market equipped with this technology, such as MPVs or city cars.

also read : Best Turbocharger Manufacturers and Suppliers in the World

How do turbochargers work?

Turbochargers use the air flow generated by burning exhaust gases as an energy source. Air flows through the turbine then rotates the compressor. The resulting rotation can reach up to 150 thousand revolutions per minute. The rotating speed is 30 times higher than normal engine without turbo. However, a new turbocharger or turbo works when the engine is running at a certain speed.

The new turbine turns when there is sufficient pressure on the exhaust gases. When the engine speed or RPM increases, the exhaust gas comes out. When the exhaust gas flow increases, the turbine also rotates faster. Turbo engines are usually equipped with an inter-radiator which stores the heat generated by the turbine rotation. The intercooler shrinks the molecules, lowering the air temperature at the inlet. The smaller the air molecules in the intake, the bigger the air molecules in the engine and the stronger the power.

The turbocharger unit consists of two blades or a turbine on a single shaft mounted on the side of the exhaust manifold. One blade or turbine is connected to the exhaust duct, while the other blade or turbine is mounted relative to the inlet air.

The two blades are in the form of wings, where when one of the blades or turbine rotates, the blade or turbine on the other side also rotates.

Here is how the complete turbocharger works, which can be listened to below:

1. How the turbine works

The first relates to exhaust gas flow, meaning that the exhaust rotates when the car engine is started because the exhaust gas energy flows through the blades.

The cylinder of a car engine under pressure throws the exhaust gases of combustion into the stream and drives the first blade or turbine.

As in a cochlea in nature, when the first blade rotates automatically, the blade connected to the air inlet or compressor also rotates.

2. The second mode of operation

A turbine or blade or rotary compressor connected to the intake air stream compresses the air by sucking it into the passing air.

The more exhaust energy that enters the first turbine, the greater the rotation of the second blade in the intake air stream.

The reason is that when the turbine rotates more air enters. You can measure it by using the turbo pressure sensor to detect the manifold pressure sent to the engine ECU.

At certain engine speeds, the turbine shaft can rotate up to 80,000 rpm.

3. The third mode of operation

Compressed air has a higher temperature. With warmer air, the air density is lower and it is less accurate to undergo the combustion process in the combustion chamber.

Therefore, you should also install an intercooler that cools the compressed air before it enters the combustion chamber or cylinder.

The shape of the intercooler is similar to a radiator which is placed in front of the car to allow outside air to easily reach, which facilitates cooling of the internal air.

After the compressed air is cooled through the intercooler, it is forced into the combustion chamber or cylinder.

4. The fourth way of working

The air entering the cylinder chamber has a higher oxygen content and denser air intensity, which helps speed up the combustion process in the cylinder chamber. The throttle, however, monitors the air entering the combustion chamber, so it knows exactly how much air is needed based on how deep the throttle is depressed.

It should be noted that while high turbine speeds are good for engine acceleration, they can affect boost pressure to some extent.

To avoid this, you can install a protector in the form of an exhaust valve, which is used to bypass the exhaust flow according to the turbocharger pressure.

5. Fifth Operation Mode

Looking at several turbocharger components such as air flow meter, turbo pressure sensor, throttle position, engine speed sensor, the turbocharger generates the engine ECU.

The engine ECU calculates the exact amount of fuel that must be injected into the combustion chamber to achieve maximum efficiency of the car engine.

In addition to engine power at maximum power, there is residual gas in the cylinder after combustion, which is discharged to reuse the turbine in the same way.

How to Care for Turbochargers in Diesel Engines

Car owners should be aware that turbochargers have a lag or lack of power from the turbo until a certain speed is reached. So even if you press the gas pedal hard, but because you haven’t reached a certain speed, the acceleration will feel like there was a pause right at the start. Here are (four) ways to care for a turbocharger engine:

1. Timely Oil Change

Turbocharger damage can actually be prevented by carrying out routine scheduled maintenance. It is recommended to check the engine oil change intervals regularly so that the quality of the engine oil is maintained and the oil filter can function normally. You can also check the engine oil pressure and keep the air filter clean.

2. Diligently check the volume of engine oil

One of the causes of damage to the turbo is old iron that gets into the turbine because the old engine oil is not replaced. On the other hand, a lack of engine oil can quickly damage a turbo. Extreme exhaust temperature due to failure of the cranking system or fuel injection can damage the turbo components.

3. Get used to engine idling before turning off the engine

The turbocharger is in a high temperature area because it uses exhaust gas energy. If you park your car immediately after driving at high speed, heat can build up in the engine bay. This happens because there is no more air flowing in the engine room. It is difficult to adapt the turbo to these conditions and can shorten the life of the turbo. Thus, after traveling at high speed, the car must be slowed down for the rest of the route.

Do not immediately park the car and turn off the engine. This can make the turbo adaptable to high temperatures but less airflow in the engine bay.

4. Clean/Replace Air Filter

Always keep the intake manifold turbo air filter clean. In this way we must diligently check the condition of the air filter and clean it if it is dirty.

If the air filter must be replaced regularly at each maintenance schedule, so that the air entering the intake through the turbo is also clean and the engine condition is maintained.

Conclusion

That’s all for a brief discussion of what a turbocharger is, its functions, benefits, and how it works. Not only knowing what a turbocharger is, but also discussing the functions, benefits, working methods and proper maintenance methods so that the engine is maintained.

Knowing what a turbocharger is for automotive enthusiasts is very useful in knowing the capacity of diesel engine-based vehicles so that they are properly cared for so that the vehicle is maintained and works optimally when used.

That’s a review of turbocharged engines. For Sinaumed’s who want to understand turbochargers and other knowledge related to the automotive world, you can visit sinaumedia.com to get related books.