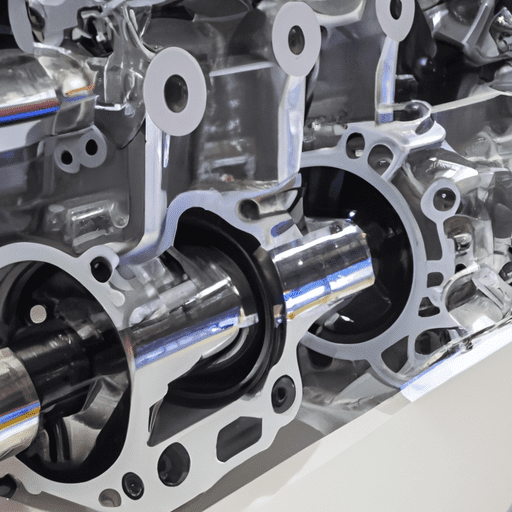

Heavy equipment is a crucial element in various industries that require the handling of heavy loads and equipment, including construction, mining, transportation, and agriculture. To keep heavy equipment engines running optimally, high-quality engine parts are crucial. Heavy equipment engines need to withstand long hours of use under heavy load, high temperatures, and rough terrain, which can result in wear and tear over time. Failing to maintain or replace worn engine parts can lead to reduced performance, costly repairs, and even equipment failure, which can result in downtime that impacts profit margins. Here are some of the benefits of using high-quality heavy equipment engine parts.

Improved Performance

Heavy equipment engines are highly complex and require intricate machinery to function smoothly. When using high-quality engine parts, even the smallest components are highly engineered to meet rigorous standards, ensuring optimal performance. Heavy equipment that runs efficiently saves fuel, reduces wear and tear, and maximizes uptime. The use of high-quality heavy equipment engine parts significantly reduces the likelihood of equipment breakdowns due to faulty components, which can result in lost productivity and increased repair costs.

Extended Equipment Life

The durability and longevity of high-quality heavy equipment engine parts ensure that equipment remains functional for more extended periods, effectively extending the equipment’s life. Heavy equipment can be incredibly expensive and making each piece last as long as possible is both financially responsible and environmentally conscious. Using low-quality or substandard engine parts can lead to frequent breakdowns and repairs, leading to more downtime and ultimately shortening the equipment’s service life.

Improved Safety

Safety is a top priority in any business. Using high-quality engine parts reduces the likelihood of equipment failure, significantly improving safety on the jobsite. When equipment is maintained appropriately, it is less likely to experience unexpected breakdowns, which can result in accidents or injuries. Furthermore, when heavy equipment is in peak condition, it can perform critical safety functions, such as braking and steering, effectively.

Cost Savings

Investing in high-quality engine parts may seem like a more significant expense upfront, but the cost savings and benefits in the long run far outweigh the initial costs. Using high-quality parts means that equipment runs more efficiently, reducing fuel consumption and maintenance costs. By extending the equipment’s lifespan, there is no need to purchase expensive replacement equipment, thereby reducing overhead costs. Additionally, high-quality engine parts are less likely to fail, reducing repair costs, downtime, and lost productivity.

Reduced Environmental Impact

Heavy equipment is known for producing harmful emissions that impact the environment. One of the primary contributors to these emissions is inefficient engines that consume excessive fuel. By using high-quality engine parts, heavy equipment engines operate more efficiently, consuming less fuel and producing fewer emissions. The use of high-quality parts also extends the equipment’s lifespan, reducing the amount of waste generated from replacing faulty or worn-out parts.

Conclusion

In conclusion, investing in high-quality heavy equipment engine parts provides numerous benefits for businesses in various industries that require the use of heavy equipment. The improved performance, extended equipment life, improved safety, cost savings, and reduced environmental impact all contribute to boosting profitability while reducing negative environmental consequences. It is crucial to note that using substandard engine parts can lead to expensive repairs, downtime, and lost productivity, highlighting the importance of investing in high-quality parts. By prioritizing the use of high-quality heavy equipment engine parts, businesses can improve their long-term outcomes and ensure that their heavy equipment runs optimally.