Autoclave is a laboratory tool used to sterilize laboratory equipment after use. Do any of you often use an autoclave? In this article, we will discuss a laboratory tool called an autoclave.

The discussion about this tool will be pretty long and complete. You are starting from the notion of the autoclave, the history autoclave, the recommendation for the autoclave for your laboratory, the function of the autoclave, the working principle of the autoclave, and using the autoclave.

It will help you understand the autoclave tool. Please comment below for those who are more experts and know more about this tool. Let’s continue reading!

- What is an autoclave?

- What is the function of an autoclave?

- How to use the autoclave?

- What are autoclaves made of?

- Can the sterilization temperature be lowered?

This article can help you understand the tool. Let’s continue to discuss them one by one.

What is Autoclave?

Autoclave is a laboratory tool used to sterilize laboratory equipment after use.

Autoclaves, known as steam sterilizers, are typically used for healthcare or industrial applications. An autoclave is a machine that uses steam under pressure to kill harmful bacteria, viruses, fungi, and spores on items placed inside a pressure vessel.

What is the autoclave function and its uses in the laboratory?

Why does laboratory equipment need to be sterilized? T

Laboratories use autoclaves to fix equipment, instruments, and infectious waste. All operators must receive training on the safe operation of the autoclave before using the equipment. Users should read and understand the owner’s manual from their particular autoclave model.

The sterilization process has many types, such as filtration, heating, sound energy, and irradiation.

The sterilization process using an autoclave is one of the best because it uses a heating process with a temperature made periodically in a particular time unit.

In an easy-to-understand case like this, suppose a hospital will perform appendicitis surgery on five patients simultaneously. Every tool used to dissect the patient, scissors, knife, or tweezers (etc.) must be sterile.

If the hospital only has two sets of surgical equipment, the equipment must be washed and sterilized before being used for the next patient. Now this sterilization process needs to be done using an autoclave. How long does this sterilization process take? Of course, each autoclave has a different period. If the sterilization process using an autoclave takes 60 minutes, then at least the period between one patient and another is 1 hour.

You may also have read some understanding of autoclaves using the Google search engine.

Wikipedia Quotes About the Definition of an Autoclave

An autoclave is a pressure chamber used to carry out industrial and scientific processes requiring elevated temperature and pressure about ambient. Autoclaves are used in medical applications to perform sterilization, in the chemical industry to cure coatings and vulcanize rubber, and for hydrothermal synthesis. Industrial autoclaves are used in industrial applications, especially in composites manufacturing.

From the definition of autoclaves above, we can conclude that autoclaves have different types and categories. In their current development, autoclaves are used in industry, medicine, and research.

History of the Autoclave in the Laboratory

In the historical process of autoclave discovery, the author did not find a source that did explain it in detail. Still, there are two names associated with the formation of the autoclave, namely:

- Denis Papin

- Charles Chamberland

Denis Papin

A man of French nationality, he was born around August 1647 and died in August 1713. Denis Papin is a physicist and mathematician; he has connections with several inventions, such as the steam digester, pressure cooker, and steam engine. And of course, we need to know autoclave has another name, steam sterilizer.

Charles Chamberland

He is a man of French nationality, born around March 1851 and died around May 1908. He was a microbiologist at the Jura Department. Charles did the development of a filter which is often known as the Chamberland filter. Charles made use of porcelain rods which had smaller pores than bacteria. So that when the liquid is passed through the filter, all bacteria are captured, and the drink is free from bacteria. Charles Chamberland rose to fame when he started the research project that led to the invention of the autoclave in 1879.

From some of this information, you will understand how the relationship between the two people above relates to forming the method in the autoclave. Denis Papin will deal with pressure on the autoclave, and Charles Chamberland will deal with bacterial sterilization.

I’d appreciate it if you could understand the working principle of the autoclave and find a common thread in its relationship with the tools invented by the two people above.

Autoclave Function

What is the function of the autoclave? Maybe that’s the question on the reader’s mind right now. Autoclave function, in general, is for sterilization of any object being sterilized. There are several types, such as:

- Medical equipment (medicine)

- Laboratory equipment (research)

- Liquid and solid media

Sterilization using an autoclave takes advantage of the heat in the water, which is converted into water vapor. Some laboratory equipment allows the sterilization process using an autoclave, but others require a sterilization process using a different method, such as an ultrasonic cleaner.

The function of the autoclave in the medical or medical field is still within the scope of sterilization. Some surgical tools or medical procedures commonly used include surgical scissors, tweezers, or a scalpel. Some of these tools are included in the devices that need to be sterilized using an autoclave.

In the process of handling medical waste, the function of the autoclave also has an important role. For example: before medical waste is disposed of, there will be a sterilization process using an autoclave. This sterilization process is categorized as quite effective or alternative when compared to burning waste and impacts the environment.

In the field of microbiology, the function of the autoclave also plays an important role. For example, in the microbial culture process, media is needed, both liquid media, semi-solid media, and solid media. Well, it’s not only first sterilization before use; after microbial observation, it is better to sterilize it before the media is disposed of as waste.

What is the working principle of an autoclave?

After knowing the function of the autoclave in the previous point, we now discuss the working principle of the autoclave.

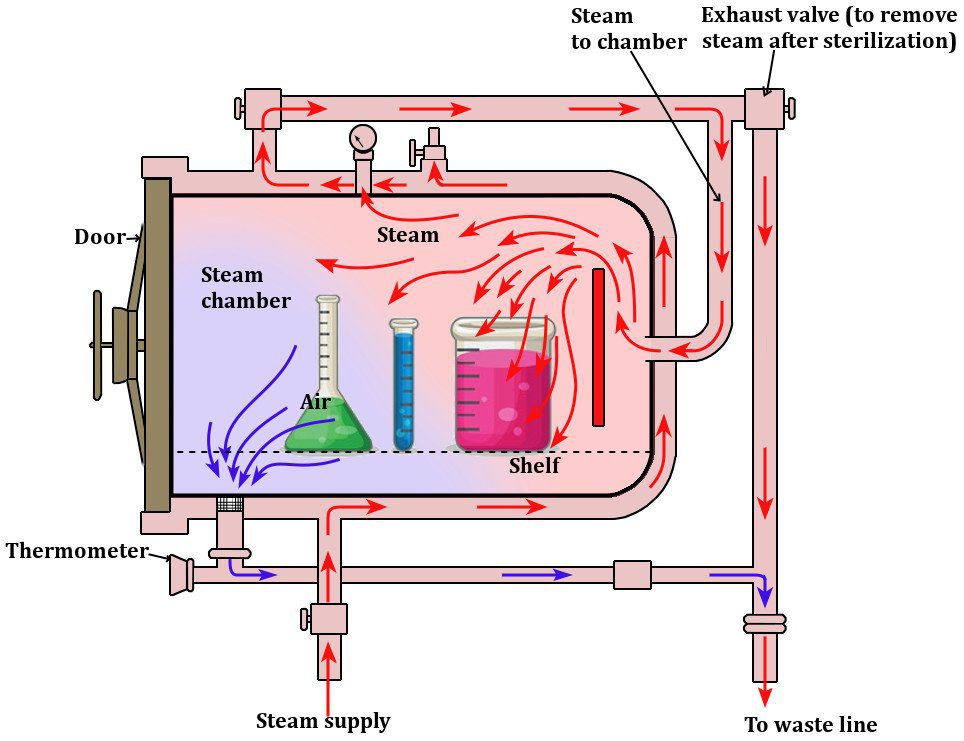

The working principle of the autoclave is straightforward: converting electrical energy into heat energy. Thermal energy is channeled into the water, the water boils and produces water vapor, and the water vapor collects and increases the pressure. Air is pushed out, and the temperature is continuously improved and controlled as needed. The heat from boiling water vapor and high pressure will be held at a particular time to kill microbes at 100 to 134°C.

The autoclave works on the principle of moist heat sterilization. The high pressure inside the chamber increases sterilizing equipment’s boiling point. The higher pressure also ensures the rapid penetration of heat into the deeper parts of the equipment.

What is the function of an autoclave and its operating temperature?

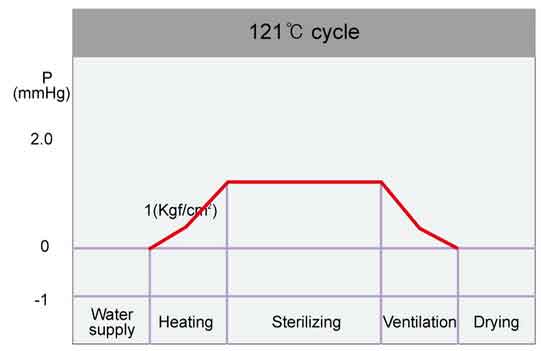

Many autoclaves are used to sterilize equipment and supplies by subjecting them to pressurized saturated steam at 121 °C (250 °F) for around 30-60 minutes at a pressure of 15 psi (103 kPa or 1.02 atm), depending on the size of the load and the contents.

In a straightforward case, the autoclave is like a rice steamer in the kitchen. I am used to steaming or heating rice. The difference is that the rice steamer uses fire as heat energy, while the laboratory autoclave uses electrical power. Some types of autoclaves that are pretty outdated may still use the stove as heating media.

Back to the electric type autoclave with automatic mode. Oh, yes… previously, there were many types of autoclaves. Such as manual, automatic, benchtop, or even large-capacity autoclaves.

In the relationship between autoclave and sterilization, several things need to be considered, such as:

- Temperature or temperature has units of degrees Celsius or Fahrenheit

- Pressure or pressure has units of bar

- The length of time for sterilization is in minutes

- The drying time has units of minutes

Several types of laboratory autoclaves are no longer manual but automatic. Automatic here refers to the cycle process according to user needs. You need to know that if the autoclave has various features, one of the features you need to know is the different treatments for sterilizing each object.

Why is an autoclave used for sterilization?

Autoclave sterilization uses heat to kill microorganisms such as bacteria and spores. The heat is delivered by pressurized steam. Pressurization allows the moisture to reach the high temperatures required for sterilization.

How to Use a Laboratory Autoclave

How to use the correct autoclave? Maybe that is the question that is on your mind. In the following, the author provides a brief overview of how to use a laboratory autoclave correctly.

If you have never used an autoclave in the laboratory before and this is your first time using an autoclave, try looking for work instructions or manuals for using an autoclave in the laboratory or a user manual that is always available when buying an autoclave. Because each autoclave usually has a different use procedure—for example, manual type autoclave and automatic type autoclave. Be sure to ask senior users if necessary.

The following are step-by-step tips on how to use a standard autoclave.

- Enter the amount of water according to the volume needed; an indicator on the reservoir can be used as an ideal benchmark because each autoclave requires a different water supply.

- Suppose your autoclave includes a sophisticated kind of autoclave so that the indicator will only be visible when there is an electricity supply (already connected). In that case, you must first click the electricity and turn on the power button.

- Place the liquid media, solid media, or laboratory equipment to be sterilized in the autoclave. Make sure you arrange them neatly; if there are shelves, agree them as neatly as possible, use them.

- Close the autoclave properly and tightly, then recheck the safety clamp before sterilizing. If the safety clamp on your autoclave is a swivel nut, ensure it is tightly closed. If your safety clamp is a swivel or sliding lever, ensure it’s tightly sealed.

- Set the time and temperature on the autoclave as needed, then press the start button. In the automatic autoclave type, you will need a cycle selection process to determine which cycle is the most appropriate for the product you will sterilize.

- After the sterilization process ends and the temperature cools down, you can only move the product out of the autoclave.

- Empty the autoclave of the sterilized product after each use. If it is not used for a long time, it is recommended to empty the water in the reservoir, disconnecting the autoclave from the power source.

Here are tips on how to use an autoclave in general. Those of you who buy a new autoclave are expected to read the manual for using the autoclave, which is available on the completeness of the purchase document.